- HOME

- Feed and compost business

Efforts of Reproduction

At Oshima Industry, we place importance on the perspective of utilizing waste for something new.

Typical examples are our feed recycling and compost recycling activities.

Feed recycling

Systematization of food circulation is realized.

High quality feed to the farm.

The Kyushu Food Industry Recycling Business Cooperative uses the waste heat from the neighboring Oshima Industry Sefuri Plant to produce feed.

It accepts unused resources and turns them into a high quality eco-field with a focus on nutritional value.

Collaborating with Oshima Industry’s Neighbor,Kyushu Food Factory Recycle B.C.A.

The systematic production process of transforming food waste into livestock feed (Eco-Feed) is made possible through collaborating with our neighbor Kyushu Food Recycle B.C.A.

-Kyushu Food Factory Recycle B.C.A.

■Founded: April 2002 (Certified by the Ministry of the Environment and the Ministry of Agriculture, Forestry and Fisheries)

■Treatment Capacity: 20t per day

■Production Capacity: 7t

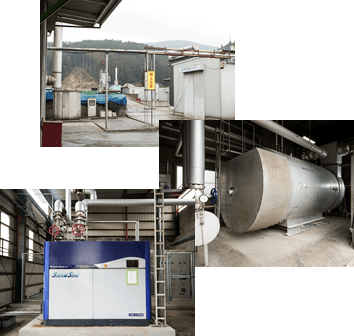

■Equipment: Vacuum Dryer Plant & Flash Dryer Plant

From Processing Waste to Producing Livestock FeedSystematic Livestock Feed Production from Food Waste

Reducing Waste and Giving Back to Clients ThroughOshima Industry's Waste Heat Recovery

Kyushu Food Factory Recycle B.C.A. utilizes waste heat emanating from the neighboring incinerator during the desiccation process. Doing so drastically reduces the fuel required to process food waste into livestock feed and reduces costs.

By inputting and transforming incineration emissions into 125〜145 degree steam, Oshima Industry harnesses heat waste to generate electricity to be used at the plant and in the desiccation process of organic waste.

Composting Recycling

Recycling of unused resources as compost

A specialized plant that realizes thermal recycling

The Oita Plant purchases vegetable waste dried by the waste heat from the incinerator at the Sefuri Plant and specializes in composting.