- HOME

- Facility Outline

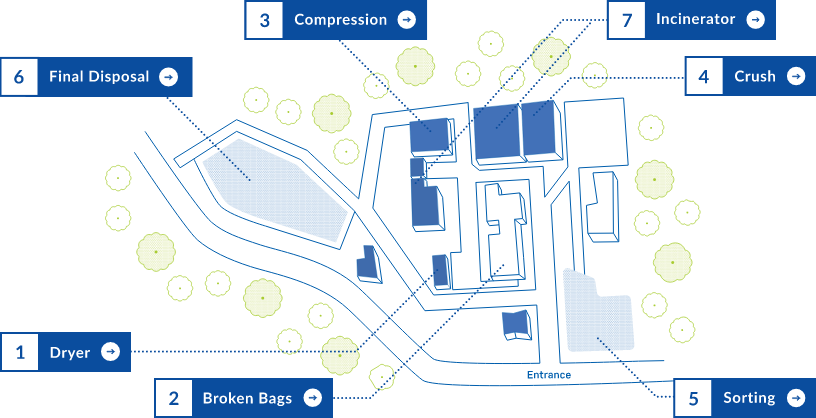

Sefuri Plant

Coexisting with the rich nature of Sefuri.

A 40,000 m² recycling plant, one of the best in Kyushu.

The Sefuri Plant is equipped with a full range of recycling facilities to convert the waste materials brought in to new resources. Each facility is powered by the waste heat from the incinerator. We are also actively engaged in thermal recycling.

1

Dryer

Using waste heat from incineration, food residues are dried and recycled as ripe compost.

Vegetable residue, sludge, animal manure

2

Broken Bags

Beverages and food products are separated into packaging materials and contents for recycling.

Waste plastics, metal scraps (limited to food containers), sludge, waste oil, waste acid, waste alkali, animal and vegetable residues (limited to food waste)

3

Compression

Waste plastics are used as cement fuel. Waste paper is used as raw material for paper manufacturing.

Waste plastics, paper waste, wood waste, fiber waste, metal waste

4

Crush

Waste with a large volume is crushed and connected to each treatment.

Waste plastics, paper waste, wood waste, fiber waste, animal and vegetable residues, rubber waste, metal waste, glass waste, concrete waste, ceramic waste, rubble

5

Sorting

Sieves according to condition to facilitate post-processing.

Cinders, sludge, waste plastics, wood waste, animal and vegetable residues, metal waste

6

Final Disposal

The leachate is purified at the water treatment facility, some of it is used for cooling water, and the rest is discharged into the river.

Cinders, sludge, paper scraps, wood scraps, fiber scraps, animal and vegetable residues, rubber scraps, mineral waste, rubble, dust, No. 13 waste, waste plastics, metal scraps, glass scraps, concrete scraps, ceramic scraps

7

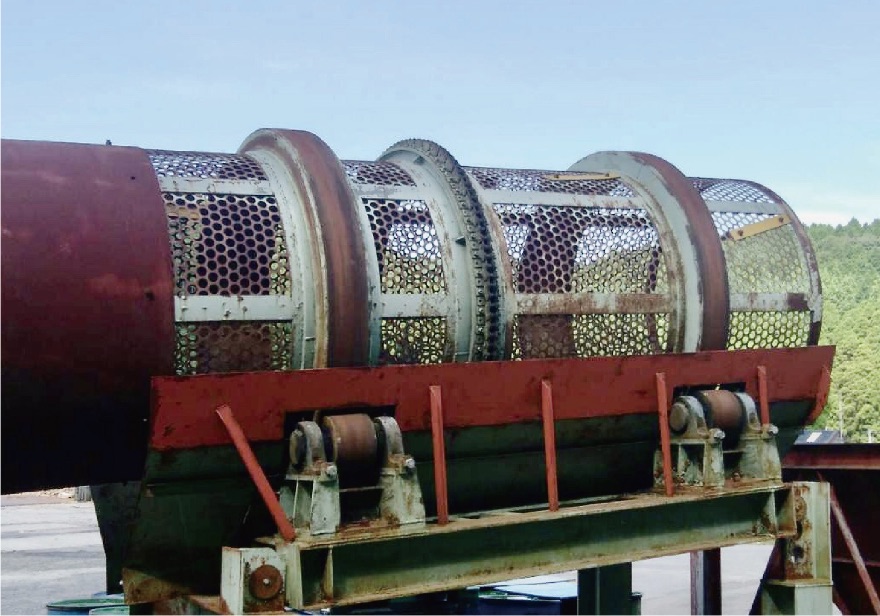

Incinerator

Thermal recycling of waste heat from incineration

"In addition to the existing two stoker-type incinerators with a daily incineration capacity of approximately 40 tons, a third rotary kiln and stoker-type incinerator is being completed in 2020.

This will provide a maximum incineration capacity of 135 tons per day. The entire process is thoroughly controlled by a central control room to ensure efficiency and safety 24 hours a day, 365 days a year."